Transition Metals (d-Block elements):

Elements formed by the filling of 3d, 4d and 5d shells of electrons comprise the d-block elements. They are also called transition elements because their position in the periodic table is between the s-block and p-block elements. Their properties are transitional between the highly reactive metallic elements of the s-block, which typically form ionic compounds, and the elements of the p-block, which are largely covalent.

Those elements or ions which have partly filled d sub-shell are called d-block elements or transition elements.

or

These elements in which the differentiating electrons occupy (n-1) d sub-shell, are d-block elements. They are called transition elements since, they show a transition in their properties from the left side (s-block) elements to the light side (p- block elements).

There are four d-series each starting with (n-1)d1ns2 constituting group3 to group 12 (or group IIIB to II B).

In the d-block, electrons are added to the penultimate shell, expanding it from 8 to 18 electrons. Typically the transition elements have an incompletely filled d level. Group 12 (the zinc group) has a d10 configuration and since the d shell is complete, compounds of these elements are not typical and show some differences from the others. The elements make up three complete rows of ten elements and an incomplete fourth row. The position of the incomplete fourth series is discussed with the f-block elements.

These elements include precious metals like silver gold, platinum and industrially important like iron, copper, nickel etc.

Electronic Configuration:

|

IIIB |

IVB |

VB |

VIB |

VIIB |

VIII |

VIII |

VIII |

IB |

IIB |

|

Sc21 Scandium |

Ti22 Zirconium |

V23 Vanadium |

Cr24 Chromium |

Mn25 Manganese |

Fe26 Iron |

CO27 Cobalt |

Mi28 Nickel |

Cu29 Copper |

Zn30 Zinc |

|

Y39 Yttrium |

Zr40 Titanium |

Nb41 Niobium |

Mo42 Molybetenium |

Te43 Technelium |

Ru44 Ruthenium |

Rh45 Rhodium |

Pd46 Palladium |

Ag47 Silver |

Cd48 Cadmium |

|

La57 Lanthanum |

Hf72 Hafnium |

Ta73 Tantalum |

W74 Tungsten |

Re75 Rhenium |

Ds76 Osmium |

Ir77 Iridium |

Pt78 Platinum |

Au79 Gold |

Hg80 Mercury |

|

Ac89 Actinium |

Rf104 Rutherford |

Db105 Dubnium |

Sg106 Seabagium |

Bh107 Bohrium |

Hs108 Hassium |

Mt109 Meitherium |

Uun110 Un-un-unium |

Uun111 Un-un-un-ium |

Unb112 Un-ub-bium |

Electronic configuration:

1st Series

|

[Ar] |

Sc |

Ti |

V |

Cr |

Mn |

Fe |

Co |

Ni |

Cu |

Zn |

|

4s |

2 |

2 |

2 |

1 |

2 |

2 |

2 |

2 |

1 |

2 |

|

3d |

1 |

2 |

3 |

5 |

5 |

6 |

7 |

8 |

10 |

10 |

2nd Series

|

[Ar] |

Sc |

Ti |

V |

Cr |

Mn |

Fe |

Co |

Ni |

Cu |

Zn |

|

4s |

2 |

2 |

2 |

1 |

2 |

2 |

2 |

2 |

1 |

2 |

|

3d |

1 |

2 |

3 |

5 |

5 |

6 |

7 |

8 |

10 |

10 |

3rd Series

|

[Xe] |

La |

Hf |

Ta |

W |

Re |

Os |

Ir |

Pt |

Au |

Hg |

|

6s |

2 |

2 |

2 |

2 |

2 |

2 |

2 |

1 |

1 |

2 |

|

5d |

1 |

2 |

3 |

4 |

5 |

6 |

7 |

9 |

10 |

10 |

Strictly speaking in Zn, Cd & Hg the differentiating electron enters the ns subshell & not the (n-1)d subshell hence, according to definition, they should be excluded from d-block elements. But, since they have almost all of their other properties similar to those of d-block elements, they are placed with them.

The general electronic configuration of d block is

[Noble gas] ns1–2 (n-1)d1–10 [Only Pd has 5s0 4d10]

Filling of the electron follows the sequence of increasing order of energy as given by Aufbau principle, alternatively by (n +λ) rule, which states that electron are filled in ns earlier than (n-1) d so as 4s is filled before 3d

5s before 4d and 6s before 5d so on ……..

But this sequence is disturbed in between, when d-orbital is about to be half or fully filled. e.g., at Cr & Cu in 1st series, Nb to Ag in 2nd & Pt & Au in 3rd series.

Cr 24 = 4s1 3d5

Cu29 = 4s1 3d10

Mo42 = 5s1 4d5

Pd46 = 5s0 4d10

Ag47 = 5s1 4d10

Pt78 = 6s1 5d9 or 6s0 5d10

Au79 = 6s1 5d10

The above elements of d-block have a similar tendency to fill their d-subshell either partially or completely and while doing so, they violate the Aufbau law. This is because half filled or completely filled d-levels are more stable due to greater exchange energy.

This exchange of e– between ns & (n-1) d is possible with constraints of stability only due to small energy difference between these subshells.

It should be noted that when e– are to be removed from 3d elements, they are removed from the outermost shell i.e., ns and not the penultimate i.e., (n-1)d so.

Illustration 1: Though copper, silver and gold have completely filled sets of d-orbitals yet they are considered as transition metals. Why?

Solution: These metals in their common oxidation states have incompletely filled d-orbitals, e.g., Cu2+ has 3d9 and Au3+ has 5d8 configuration.

Illustration 2: Which out of the following is/are transition element/s and why?

Solution: Ag and Au are transition elements because they have incompletely filled d-subshell.

Abundance:

Three of the transition metals are very abundant in the earth’s crust. Fe – the fourth most abundant element by weight, Ti – the ninth and Mn – the twelfth. The first row of transition elements largely follow Harkins’ rule that elements with an even atomic number are in general more abundant than their neighbours with odd atomic numbers. Manganese is an exception. The second and third row elements are much less abundant than the first row. Tc does not occur in nature. Of the last six elements in the second and third rows (Tc. Ru. Rh. Pd, Ag. Cd Re, Os. lr, Pt, Au, Hg) none occurs to an extent of more than 0.16 parts per million (ppm) in the earth’s crust.

Abundance (in ppm):

|

Sc |

Ti |

V |

Cr |

Mn |

Fe |

Co |

Ni |

Cu |

Zn |

|

25 |

6320 |

136 |

122 |

1060 |

60000 |

29 |

99 |

68 |

76 |

|

Y |

Zr |

Nb |

Mo |

Tc |

Ru |

Rh |

Pd |

Ag |

Cd |

|

31 |

162 |

20 |

1.2 |

– |

0.0001 |

0.0001 |

0.015 |

0.08 |

0.16 |

|

La |

Hf |

Ta |

W |

Re |

Os |

Ir |

Pt |

Au |

Hg |

|

35 |

2.8 |

1.7 |

1.2 |

0.0007 |

0.005 |

0.001 |

0.01 |

0.004 |

0.08 |

Physical properties:

1) Metallic character:

In the d-block elements the penultimate shell of electrons is expanding. Thus they have many physical and chemical properties in common. Thus all the transition elements are metals. They are therefore good conductors of electricity and heat, have a metallic lustre and are hard, strong and ductile. They also form alloys with other metals.

All d-block elements are metals. Unlike s-blocks they are hard, malleable and ductile with very high mp & bp’s. Hardness and high mp indicate strong binding forces in their crystals.

They are good conductor of electricity and have metallic lusture due to delocalization e– over the entire crystal structure.

In a transition series the no. of unpaired e– increases from IIIB to VI B and then decreases (due to pairing up). So, the metallic lattice becomes stronger upto group VIB whereafter it decreases slowly.

Moving across a period, there is gradual decrease in the electropositive character. The strong metallic bonding in transition metals is due to greater effective nuclear charge and large no. of valence electrons (here all the electrons outside the noble gas configuration [i.e., ns & (n-1)d] are considered to be valence e–)

It is only the metallic bonding which accounts the metals to be good conductor of heat and electricity and their high density.

Illustration3: Transition metals exhibit higher enthalpies of atomization. Explain why?

Solution: Enthalpy of atomsation is the amount of heat required to break the metal lattice to get free atoms. As transition metals contain a large number of unpaired electrons, they have strong inter atomic attractions (metallic bonds). Hence, they have high enthalpies of atomization.

Atomic and Ionic Radii:

The covalent radii of the elements (see table) decrease from left to right across a row in the transition series, until near the end when the size increases slightly. On passing from left the right, extra protons are placed in the nucleus and extra orbital electrons are added. The orbital electrons shield the nuclear charge incompletely (d electrons shield less efficiently than p electrons, which in turn shield less effectively than s electrons). Because of this poor screening by d electrons, the nuclear charge attracts all of the electrons more strongly: hence a contraction in size occurs.

Atoms of the transition elements are smaller than those of the Group 1 or 2 elements in the same horizontal period. This is partly because of the usual contraction in size across a horizontal period discussed above, and partly because the orbital electrons are added to the penultimate d shell rather than to the outer shell of the atom. Interposed between lanthanum and hafnium are the 14 lanthanide elements, in which the antepenultimate 4f shell of electrons is filled.

Table: Covalent radii of the transition elements (Å)

|

K |

Ca |

Sc |

Ti |

V |

Cr |

Mn |

Fe |

Co |

Ni |

Cu |

Zn |

|

1.57 |

1.74 |

1.44 |

1.32 |

1.22 |

1.17 |

1.17 |

1.17 |

1.16 |

1.15 |

1.17 |

1.25 |

|

Rb |

Sr |

Y |

Zr |

Nb |

Mo |

Tc |

Ru |

Rh |

Pd |

Ag |

Cd |

|

2.16 |

1.91 |

1.92 |

1.45 |

1.34 |

1.29 |

|

1.24 |

1.25 |

1.28 |

1.34 |

1.41 |

|

Cs |

Ba |

La * |

Hf |

Ta |

W |

Re |

Os |

Ir |

Pt |

Au |

Hg |

|

2.35 |

1.98 |

1.69 |

1.44 |

1.34 |

1.30 |

1.28 |

1.26 |

1.26 |

1.29 |

1.34 |

1.44 |

*14 Lanthanide elements

Table: The effect of the lanthanide contraction on ionic radii

|

Ca2+ |

1.00 |

Sc3+ |

0.745 |

|

Ti4+ |

0.605 |

V3+ |

0.64 |

|

Sr2+ |

1.18 |

Y3+ |

0.90 |

|

Zr4+ |

0.72 |

Vb3+ |

0.72 |

|

Ba2+ |

1.35 |

La3+ |

1.032 |

* |

Hf4+ |

0.71 |

Ta3+ |

0.72 |

*Lanthanides

There is a gradual decrease in size of the 14 lanthanide elements from cerium to lutetium. This is called the lanthanide contraction. The lanthanide contraction cancels almost exactly the normal size increase on descending a group of transition elements. The covalent radius of I-If and the ionic radius of Hf are actually smaller than the corresponding values for Zr. The covalent and ionic radii of Nb are the same as the values for Ta. Therefore the second and third row transition elements have similar radii. As a result they also have similar lattice energies, solvation energies and ionization energies. Thus the differences in properties between the first row and second row elements are much greater than the differences between the second and third row elements. The effects of the lanthanide contraction are less pronounced towards the right of the d-block. However, the effect still shows to a lesser degree in the p-block elements which follow.

Illustration 4: Which out of the two, La(OH)3 and Lu(OH)3, is more basic and why?

Solution: La (OH)3 is more basic than Lu (OH)3. As the size of the lanthanide ions decreases from La3+ to Lu3+, the covalent character of the hydroxides increases (Fajan’s rules). Hence, the basic strength decreases from La (OH)3 to Lu (OH)3.

Density:

The atomic volumes of the transition elements are low compared with elements in neighbouring Groups 1 and 2. For a transition series density increases across the period on moving left to right, attains a maximum value at group VIII & then decreases. However moving down a group density increases substantially since atomic radii remain almost same, while mass is increasing (almost doubled). The reason is the smaller radii and close packed structure. In addition, the extra electrons added occupy inner orbitals. Consequently the densities of the transition metals are high. Practically all have a density greater than 5 g cm–3 (The only exceptions are Sc 3.0 g cm–3 and Y and Ti 4.5 g cm–3. The densities of the second row are high and third row values are even higher. The two elements with the highest densities are osmium 22.57g cm–3 and iridium 22.61 g cm–3. So, a football made of osmium or iridium measuring 30 cm in diameter would weigh 320 kg or almost one third of a tonne!

|

Transition series |

Element |

At radius (Å) |

At mass (amu) |

Density (g cm–3) |

Element |

At radius (Å) |

At mass (amu) |

Density (g cm–3) |

|

IInd series |

Nb |

1.46 |

93 |

8.4 |

M0 |

1.39 |

96 |

10.4 |

|

IIIrd series |

Ta |

1.46 |

181 |

16.6 |

W |

1.36 |

184 |

19.3 |

Note: Osmium (Os) has the highest density of 22.6 g cm –3 of all the elements.

MP & BP: The melting and boiling points of the transition elements are generally very high. Transition elements typically melt above 1000°C. Three elements melt above 3000°C (Ta 3000°C, W 3410°C and Re 3180°C). There are a few exceptions. The melting points of La and Ag are just under 1000°C (920°C and 961°C respectively). Other notable exceptions are Zn (420°C), Cd (321 °C) and Hg which is liquid at room temperature and melts at —38°C. The last three behave atypically because the d shell is complete, and d electrons do not participate in metallic bonding. The high melting points are in marked contrast to the low melting points for the s-block metals Li (181 °C) and Cs (29°C).

Ionization energies:

There is an increase in the ionization energy but the increase is less compared to s or p block elements of the same period. For example: IE of Sc, Ti, V & Cr are fairly close to one another. Similarly values for Fe, Co, Ni & Cu are also very close. The reason being the screening effect of d-electrons which compensates the increment in nuclear charge. However the values lie between s & p blocks on either side.

The change for 2nd IE is more smooth with only variation at Cr (3d5) and Cu (3d10) due to most stable d subshells – configurations. Similarly for 3rd IE Mn & Zn have sufficiently higher values for the same reason.

Reactivity:

Many of the metals are sufficiently electropositive to react with mineral acids, liberating H2. A few have low standard electrode potentials and remain unreactive or noble. Noble character is favoured by high enthalpies of sublimation, high ionization energies and low enthalpies of solvation. (Born-Haber cycle) The high melting points indicate high heats of sublimation. The smaller atoms have higher ionization energies. But this is offset by small ions having high solvation energies. This tendency to noble character is most pronounced for the platinum metals (Ru, Rh, Pd, Os, Ir, Pt) and gold.

Oxidation state:

One of the most striking features of the transition elements is that the elements usually exist in several oxidation states. Furthermore, the oxidation states change in units of one, e.g. Fe (II) and Fe (III); Cu (I) and Cu (II). The oxidation states shown by the transition elements may be related to their electronic structures. Calcium, the s-block element preceding the first row of transition elements, has the electronic structure:

Ca = 1s22s22p63s23p6 4s2

It might be expected that the next ten transition elements would have this electronic arrangement with from one to ten d electrons added in a regular way: 3d1, 3d2, 3d3 …… 3d10. This is true except in the cases of Cr and Cu. In these two cases one of the s electrons moves into the d shell, the additional stability when the d orbitals are exactly half filled or completely filled.

In contrast to s-block elements which have +I & +II respectively, transition elements can exist in a variety of ox. states. These states depend on the no. of e– in outermost subshell ‘plus’ penultimate subshell. The maximum valency that an element of d-block can exhibit is found to increase from 3rd group to 7th or 8th thereafter it decreases upto 12th.

Oxidation states of d-block elements:

|

Element |

Sc |

Ti |

V |

Cr |

Mn |

Fe |

Co |

Mi |

Cu |

Zn |

|

Oxidation states |

(+2) |

+2 |

+2 |

+1 |

+2 |

+2 |

+2 |

+2 |

+2 |

+2 |

|

|

+3 |

+3 |

+3 |

+3 |

+3 |

+3 |

+3 |

+3 |

|

|

|

|

|

+4 |

+4 |

+4 |

+4 |

+4 |

+4 |

|

|

|

|

|

|

+5 |

|

|

|

|

|

|

|

|

|

|

|

|

+6 |

+6 |

+6 |

|

|

|

|

|

|

|

|

|

|

+7 |

|

|

|

|

|

|

Note the difference between variable valency of p block (heavy atoms) with d blocks – in p-block the difference of the two states was always 2 i.e., TlI & TlII PbII & PbIV, SbIII & SbIV etc due to inert inner 2s e– but here the difference is one i.e., FeII, FeIII, CoII & CoIII, CuI & CuII. Here the reason is mainly the no. of e– in d subshell.

Thus Sc could have an oxidation number of (+ II) if both s electrons are used for bonding and (+III) when two s and one d electrons are involved. Ti has an oxidation state (+II) when both s electrons are used for bonding, (+III) when two s and one d electrons are used and (+IV) when two sand two d electrons are used. Similarly, V shows oxidation numbers (+II), (+III) (+IV) and (+VI). In the case of Cr, by using the singles electron for bonding, we get an oxidation number of (+I): hence by using varying numbers of d-electrons oxidation states of (+II), (+III), (+V) and (+Vl) are possible. Mn has oxidation states (+II). (+III), (+IV), (+V), (+V1) and (+VII). Among these first five elements, the correlation between electronic structure and minimum and maximum oxidation states in simple compounds is complete. In the highest oxidation state of these first five elements, all of the s and d electrons are being used for bonding. Thus the properties depend only on the size and valency and consequently show some similarities with elements of the main groups in similar oxidation states. For example, SO42– (Group 16) and CrO42– (Group 6) are isostructural as are SiCl4 (Group 14) and TiCl4 (Group 4). Once the d configuration is exceeded, i.e. in the last five elements the tendency for all the d electrons to participate in bonding decreases. Thus Fe has a maximum oxidation state of (+VI). However, the second and third elements in this group attain a maximum oxidation state of (+ VIII), in RuO4 and OsO4. This difference between Fe and the other two elements Ru and Os is attributed to the increased size of the latter two elements where all the 6d and 2s e– be removed.

These facts may be conveniently memorized, because the oxidation states form a regular ‘pyramid’ as shown in Table. Only Sc(+II) and Co(+V) are in doubt. The oxidation number of all elements in the elemental state is zero. In addition, several of the elements have zero valent and other low-valent states in complexes. Low oxidation states occur particularly with n bonding ligands such as carbon monoxide and dipyridyl. Similar but not identical pyramids of oxidation states are found in the second and third rows of transition elements. The main differences are as follows:

1. In Group 8 (the iron group) the second and third row elements show a maximum oxidation state of (+V1Jl) compared with (+VI) for Fe.

2. The electronic structures of the atoms in the second and third rows do not always follow the pattern of the first row. The structures of group 10 elements (the nickel group) are:

Ni 3d8 4s2

Pd 4d10 5s0

Pt 5d9 6s1

Since a full shell of electrons is a stable arrangement, the place where this occurs is of importance.

The 4 levels are complete at copper, palladium and gold in their respective series.

|

Ni |

3d8 |

4s2 |

Cu |

3d10 |

4s1 |

Zn |

3d10 |

4s2 |

|

Pd |

4d10 |

5s0 |

Ag |

4d10 |

5s1 |

Cd |

4d10 |

5s2 |

|

Pt |

5d9 |

6s1 |

Au |

5d10 |

6s1 |

Hg |

5d10 |

6s2 |

The maximum ox. st of an element with reasonable stability corresponds to the value of no. of e– in ns + (n-1)d subshells upto Mn; thereafter it decreases upto Cu. (s, p, d & f should not be called orbitals. They actually are subshells; they are made up of orbitals e.g., p subshell comprises of px, py & pz orbitals).

There is a difference in valency & ox. state. Oxidation no. is the residual charge left over an atom of a compound, if all the rest atoms are replaced in ionic form, while valency is the no. of e– that take bart in formation of a compound – either through ionic or covalent bond formation. Abrupt decrease of stability in the higher stable oxidation state is observed. Due to no. of e– in ns subshell the minimum ox no. I or II can be accounted for, but there is no regular rule for maximum ox. st.

Stability of the various oxidation states:

Compounds are regarded as stable if they exist at room temperature, are not oxidized by the air, are not hydrolysed by water vapour and do not disproportionate or decompose at normal temperatures. Within each of the transition Groups 3—12, there is a difference in stability of the various oxidation states that exist. In general the second and third row elements exhibit higher coordination numbers, and their higher oxidation states are more stable than the corresponding first row elements. This can be seen from Table. This gives the known oxides and halides of the first, second and third row transition elements. Stable oxidation states form oxides, fluorides, chlorides, bromides and iodides. Strongly reducing states probably do not form fluorides and/or oxides, but may well form the heavier halides. Conversely, strongly oxidizing states form oxides and fluorides, but not iodides.

Oxides and halides of the first row

|

|

|

Sc |

Ti |

V |

Cr |

Mn |

Fe |

Co |

Ni |

Cu |

Zn |

|

+ II |

O |

|

TrO |

VO |

CrO |

MnO |

FeO |

CeO |

NiO |

CuO |

ZnO |

|

|

F |

|

|

VF2 |

CrF2 |

MnF2 |

FeF2 |

CoF2 |

NiF2 |

CuF2 |

ZNF2 |

|

|

Cl |

|

HCl2 |

VCl2 |

CrCl2 |

MnCl2 |

FeCl2 |

CoCl2 |

NiCl2 |

CuCl2 |

ZnCl2 |

|

|

Br |

|

TiBr2 |

VBr2 |

CrBr2 |

MnBr2 |

FeBr2 |

CoBr2 |

NiBr2 |

CuBr2 |

ZnBr2 |

|

|

I |

|

Til2 |

Vl2 |

Crl2 |

Mnl2 |

Fel2 |

Col2 |

Nil2 |

|

Znl2 |

|

+III |

O |

Se2O3 |

Ti2O3 |

V2O3 |

Cr2O3 |

Mn2O3 |

(Co2O3)b |

(Ni2O3)b |

|

|

|

|

|

F |

SeF3 |

TiF3 |

CrF3 |

MnF3 |

FeF3 |

CoF3 |

|

|

|

|

|

|

Cl |

SeCl3 |

TiCl3 |

VCl3 |

|

FeCl3 |

|

FeCl3 |

|

|

|

|

|

Br |

SeBr3 |

TiBr3 |

VBr3 |

CrBr3 |

|

|

FeBr3 |

|

|

|

|

|

I |

Sel3 |

Til3 |

Til3 |

Vl3 |

Crl3 |

|

|

|

|

|

|

+IV |

O |

TiO2 |

VO2 |

CrO2 |

MnO2 |

|

(CoO2)b |

N2O3b |

|

|

|

|

|

F |

|

TiF4 |

VF4 |

CrF4 |

MnF4 |

|

|

|

|

|

|

|

Cl |

|

TiCl4 |

VCl4 |

CrCl4 |

|

|

|

|

|

|

|

|

Br |

TiBr4 |

VBr4 |

CrBr4g |

|

|

|

|

|

|

|

|

|

I |

Til4 |

|

Crl4 |

|

|

|

|

|

|

|

|

+V |

O |

|

V2O3 |

|

|

|

|

|

|

|

|

|

|

F |

|

VF4 |

CrF3 |

|

|

|

|

|

|

|

|

|

Cl |

|

|

|

|

|

|

|

|

|

|

|

|

Br |

|

|

|

|

|

|

|

|

|

|

|

|

I |

|

|

|

|

|

|

|

|

|

|

|

+VI |

O |

|

|

CrO4 |

|

|

|

|

|

|

|

|

|

F |

|

|

(CrF0) |

|

|

|

|

|

|

|

|

|

Cl |

|

|

|

|

|

|

|

|

|

|

|

|

Br |

|

|

|

|

|

|

|

|

|

|

|

|

I |

|

|

|

|

|

|

|

|

|

|

|

+VII |

O |

|

|

|

|

Mn2O7 |

|

|

|

|

|

|

|

F |

|

|

|

|

|

|

|

|

|

|

|

|

Cl |

|

|

|

|

|

|

|

|

|

|

|

|

Br |

|

|

|

|

|

|

|

|

|

|

|

|

I |

|

|

|

|

|

|

|

|

|

|

|

Other compounds |

|

|

|

|

Mn2O3 |

Fe3O4 |

Co3O4 |

|

Cu2O |

|

|

|

|

|

|

|

|

|

|

|

|

CuCl |

|

|

|

|

|

|

|

|

|

|

|

|

CuBr |

|

|

|

|

|

|

|

|

|

|

|

|

Cul |

|

|

For the first transition series the most common ox. st. with all the elements is +2 which is the minimum ox. st. shown by the d block elements (except group 11 or IB and Hg which exhibit +1 in addition to higher values).

Some transition metals show zero oxidation state with strong p acid ligands*, and sometimes even ‘negative’ values are observed; e.g.,

Ni (CO)4 Ni (0)

Fe(CO)5 Fe(0)

Na (Mn (CO)5] Mn (-I)

The compounds wherein elements reflect their highest oxidation state are those of having small sized & high electronegativity atoms as anions (like F– & O2–)

The maximum ox. st in

|

1st transition series |

Mn |

(VII) |

(3d5 4s2) |

|

2nd transition series |

Ru |

(VIII) |

4d6 5s2) |

|

3rd transition series |

Os |

(VIII) |

(5d66s2) |

Illustration 5: Why do transition elements show variable oxidation states?

Solution: In the transition elements, the energies of (n – 1) d –orbitals and ns orbitals are very close. Hence, electrons from both can participate in bonding.

Illustration 6: Decide giving reason which one of the following pairs exhibits the property indicated:

V or Mn exhibits more number of oxidation states (Atomic numbers: Sc = 21, Cr = 24, V = 23, Mn = 25)

Solution: Mn exhibits more number of oxidation states.

π-acid ligands:

These are the ions or molecules which have π bond in them and are able to form back bonding with metal due to presence of a vacant orbital. These vacant orbitals of the ligand can accept electron pair from metal & thus behaving as a ligand (donor) as well as an acid (a Lewis acid – an acceptor).

As usually ligands are the electrons donors and they donate a lone pair to metal and behave as a Lewis base. But in case of CO, i.e., carbon monoxide due to resonating structure has an extra lone pair which is donated to the metal atom forming an organometallic (actually C → M) bond.

At the same time, the increased charge density over the metal atom is localized over the available antibonding orbitals of CO forming a π-bond with the filled d-orbital of metal.

Tendency to form complexes:

Since these elements have either empty d-orbitals or they can achieve a configuration with it which can accommodate e– from the ligands (the molecules with at least an unshared e– paired like, CO, NO, NH3, H2O, F–, Cl– CN– etc).

The factor that determine the extent of complex formation are

(i) Small size and high charge density

(ii) Presence of vacant d orbitals

Because of presence of coordinate bond between metal cation and ligands, the complexes are called coordination compounds.

Complexes:

The transition elements have an unparalleled tendency to form coordination compounds with Lewis bases, that is with groups which are able to donate an electron pair. These groups are called ligands. A ligand may be a neutral molecule such as NH3 or an ion such as Cl– or CN–. Cobalt forms more complexes than any other element, and forms more compounds than any other element except carbon.

Co3+ + 6NH3 → [Co(NH3)6]3+

Fe2+ + 6CN– → [Fe(CN)6]4–

This ability to form complexes is in marked contrast to the s- and p-block elements which form only a few complexes. The reason why transition elements are so good at forming complexes is that they have small, highly charged ions and have vacant low energy orbitals to accept lone pairs of electrons donated by other groups or ligands. Complexes where the metal is in the (+III) oxidation state are generally more stable than those where the metal is in the (+II) state.

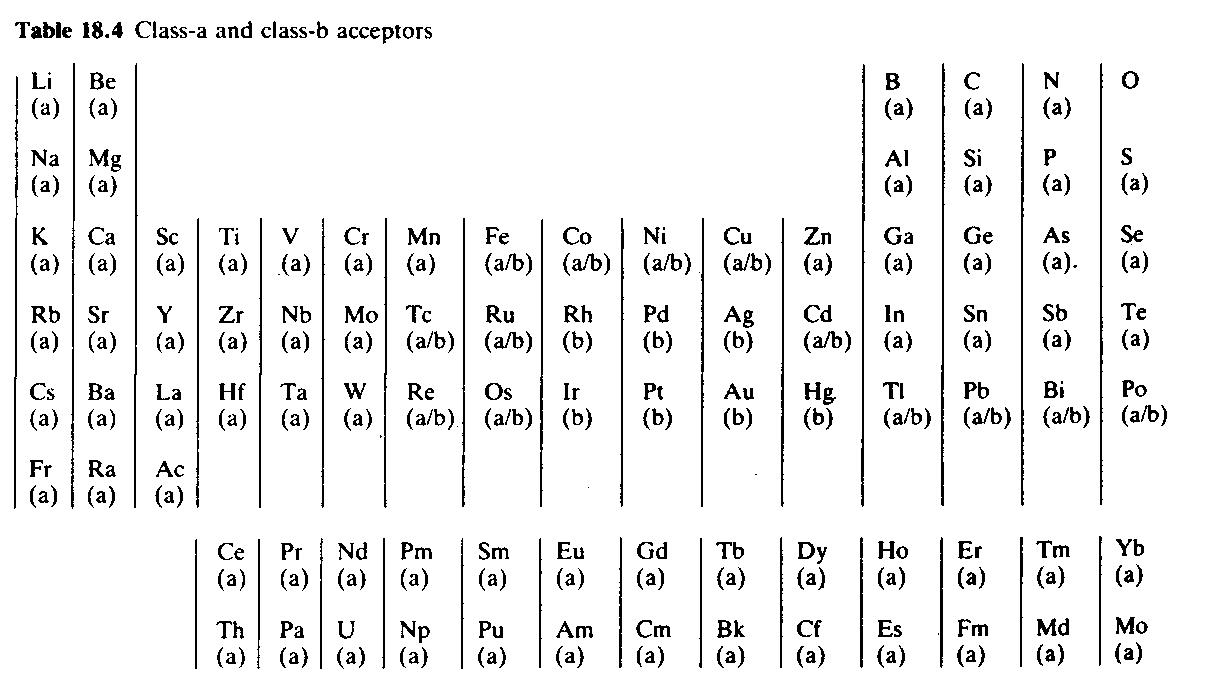

Some metal ions form their most stable complexes with ligands in which the donor atoms are N, O or F. Such metal ions include Group 1 and 2 elements, the first half of the transition elements, the lanthanides and actinides, and the p-block elements except for their heaviest member. These metals are called class-a acceptors, and correspond to ‘hard’ acids (see ‘Acids and bases’). In contrast the metals Rh, Ir, Pd, Pt, Ag, Au and Hg form their most stable complexes with the heavier elements of Groups 15, 16 and 17. These metals are called class-b acceptors, and correspond to ‘soft’ acids. The rest of the transition metals, and the heaviest elements in the p-block, form complexes with both types of donors, and are thus ‘intermediate’ in nature. These are shown (a/b) in Table.

The nature of coordination complexes and the important crystal field theory of bonding are discussed in the next chapter.

Standard electrode potential (E0) and chemical reactivity:

The standard Red. Pot. (E0 Mn+/M) of the d block elements are ‘negative’ (i.e., less than that of H, 0.00 volt) except Cu, Ag, Au, Pt, Hg but ‘less negative’ than s block elements (Na, K, Ca, Mg). So they are comparatively less reactive and their reducing prop. is less than alkali & alkaline earth metals.

The less value of E0 is due to high ionization energy & sublimation energy (or enthalpy of atomization) coupled with less hydration enthalpy, as

Colour:

Many ionic and covalent compounds of transition elements are coloured. In contrast compounds of the s- and p-block elements are almost always white. When light passes through a material it is deprived of those wave lengths that are absorbed. If absorption occurs in the visible region of the spectrum, the transmitted light is coloured with the complementary colour to the colour of the light absorbed. Absorption in the visible and UV regions of the spectrum is caused by changes in electronic energy. Thus the spectra are sometimes called electronic spectra. It is always possible to promote an electron from one energy level to another. However, the energy jumps are usually so large that the absorption lies in the UV region. Special circumstances can make it possible to obtain small jumps in electronic energy which appear as absorption in the visible region.

Illustration 7: Why Zn2+ salts are white while Cu2+ salts are blue?

Solution: It is because of presence of unpaired electrons in d subshells. Cu2+ has incompletely filled d-orbitals (3d9).

Illustration 8: Scandium forms no coloured ions, yet it is regarded as a transition element. Explain why?

Solution: Scandium in the ground state has one electron in the 3d-subshell, it is regarded as a transition element.

Polarization:

NaCI, NaBr and NaI are all ionic, and are all colourless. AgCI is also colourless. Thus the halide ions CI–, Br– and I–, and the metal ions Na+ and Ag+ are typically colourless. However, AgBr is pale yellow and AgI is yellow. The colour arises because the Ag ion polarizes the halide ions. This means that it distorts the electron cloud, and implies a greater covalent contribution. The polarizability of ions increases with size: thus I– is the most polarized, and is the most coloured. For the same reason Ag2CO3 and Ag3PO4 are yellow, and Ag2O and Ag2s are black.

Incompletely filled d or f shells:

Colour may arise from an entirely different cause in ions with incomplete d or f shells. This source of colour is very important in most of the transition metal ions. In a free isolated gaseous ion the five d orbitals are degenerate that is they are identical in energy. In real life situations the ion will be surrounded by solvent molecules if it is in solution, by other ligands if it is in a complex. or by other ions if it is in a crystal lattice. The surrounding groups affect the energy of some d orbitals more than others.

Thus the d orbitals are no longer degenerate, and at their simplest they form two groups of orbitals of different energy. Thus in transition element ions with a partly filled d shell it is possible to promote electrons from one d level to another d level of higher energy. This corresponds to a fairly small energy difference, and so light is absorbed in the visible region. The colour of a transition metal complex is dependent on how big the energy difference is between the two d levels. This in turn depends on the nature of the ligand, and on the type of complex formed. Thus the octahedral complex [Ni(NH3)6]2+ is blue, [Ni(H2O)6]2+ is green and [Ni(NO2)6]4– is brown-red. The colour changes with the ligand used. The colour also depends on the number of ligands and the shape of the complex formed.

The source of colour in the lanthanides and the actinides is very similar, arising from f-f transitions. With the lanthanides the 4f orbitals are deeply embedded inside the atom, and are well shielded by the 5s and 5p electrons. The f electrons are practically unaffected by complex formation: hence the colour remains almost constant for a particular ion regardless of the ligand. The absorption bands are also very narrow.

Some compounds of the transition metals are white, for example ZnSO4 and TiO2 In these compounds it is not possible to promote electrons within the d level. Zn has a d10 configuration and the d level is full. Ti has a d° configuration and the d level is empty. In the series Sc(+III), Ti(+IV), V(+V), Cr(+VI) and Mn(+VII) ions may all be considered to have an empty d shell: hence d—d spectra are impossible and they should be colourless. However, as the oxidation number increases these states become increasingly covalent. Rather than form highly charged simple ions, oxoions are formed TiO2+ VO2+, VO42– CrO42– and MnO4–. VO2+ is pale yellow, but CrO42– is strongly yellow coloured, and MnO4– has an intense purple colour in solution though the solid is almost black.

The colour arises by charge transfer. In MnO4– an electron is momentarily transferred from O to the metal, thus momentarily changing O2– to O– and reducing the oxidation state of the metal from Mn(VII) to Mn(VI).

The s-and p-block elements do not have a partially filled d shell so there cannot be any d—d transitions. The energy to promote an s or p-electron to a higher energy level is much greater and needs ultraviolet light to be absorbed. Thus compounds of s- and p-block elements typically are not coloured.

Magnetic Properties:

When a substance is placed in a magnetic field of strength H. the intensity of the magnetic field in the substance may be greater than or less than H. If the field in the substance is greater than H, the substance is paramagnetic. It is easier for magnetic lines of force to travel through a paramagnetic material than through a vacuum. Thus paramagnetic materials attract lines of force, and, if it is free to move, a paramagnetic material will move from a weaker to a stronger part of the field. Paramagnetism arises as a result of unpaired electron spins in the atom.

If the field in the substance is less than H, the substance is diamagnetic. Diamagnetic materials tend to repel lines of force. It is harder for magnetic lines of force to travel through diamagnetic materials than through a vacuum, and such materials tend to move from a stronger to a weaker part of a magnetic field. in diamagnetic compounds all the electron spins are paired.

The paramagnetic effect is much larger than the diamagnetic effect.

It should be noted that Fe, Co and Ni are ferromagnetic. Ferromagnetic materials may be regarded as a special case of paramagnetism in which the moments on individual atoms become aligned and all of them point in the same direction. When this happens the magnetic susceptibility is greatly enhanced compared with if all the moments behaved independently. Alignment occurs when materials are magnetized, and Fe, Co and Ni can form permanent magnets. Ferromagnetism is found in several of the transition metals and their compounds.

It is also possible to get antiferromagnetism by pairing the moments on adjacent atoms which point in opposite directions. This gives a magnetic moment less than would be expected for an array of independent ions. It occurs in several simple salts of Fe, Mn and Gd Since ferromagnetism and antiferromagnetism depend on orientation, they disappear in solution.

Many compounds of the transition elements are paramagnetic, because they contain partially filled electron shells. If the magnetic moment is measured, the number of unpaired electrons can be calculated. The magnetochemistry of the transition elements shows whether the d electrons are paired. This is of great importance in distinguishing between high-spin and low-spin octahedral complexes.

There are two common methods of measuring magnetic susceptibilities: the Faraday and the Gouy methods.

The magnetic moment of a transition metal can give important information about the number of unpaired electrons present in the atom and the orbitals that are occupied, and sometimes indicates the structure of the molecule or complex. lithe agnetic moment is due entirely to the spin of unpaired electrons p. then

where S is the total spin quantum number. This gives the magnetic moment in SI units of JT’, and the magnetic moment in Bohr magnetons is given by (4S(S + I)). This equation is related to the number of unpaired electrons n by the equation:

The observed magnetic moment may be considered to arise only from unpaired spins. The spin-only magnetic moment t may be written:

The number of unpaired spins n by the equation:

The spin-only results are shown in Table. The simple spin-only moments shown in table give good agreement with many high-spin complexes of first row elements

Spin only magnetic moments for numbers of unpaired electrons:

|

Number of unpaired electrons n |

Magnetic moment μS (BM) |

Total spin quantum number S |

|

1 |

1.73 |

1/2 |

|

2 |

2.83 |

2/2 = 1 |

|

3. |

3.87 |

3/2 |

|

4. |

4.90 |

4/2 = 2 |

|

5. |

5.92 |

5/2 |

Magnetic moments of some first row complexes:

|

Ion |

Number of unpaired electrons |

Experimental magnetic moment (BM) |

Calculated magnetic moment spin only formula μs (BM) |

|

Ti`3+ |

1 |

1.7-1.8 |

1.73 |

|

V3+ |

2 |

2.8-3.1 |

2.83 |

|

Cr3+ |

3 |

3.7-3.9 |

3.87 |

|

Cr2+, Mn3+ |

4 |

4.8-4.9 |

4.90 |

|

Mn2+, Fe3+ |

5 |

5.7–6.0 |

5.92 |

|

Fe2+ |

4 |

5.0-5.6 |

4.90 |

|

Co2+ |

3 |

4.3-5.2 |

3.87 |

|

Ni2+ |

2 |

2.9–3.9 |

2.83 |

|

Cu2+ |

1 |

1.9-2.1 |

1.73 |

Illustration 9: Of the ions Co2+, Sc3+ and Cr3+, which ones will give coloured aqueous solutions and how will each of them respond to a magnetic field and why?

(Atomic numbers: Co = 27, Cr = 24).

Solution: Co2+ and Cr3+ have unpaired electrons in the 3d subshell. Hence, they will give coloured solutions and attracted by the magnetic field. Sc3+ has no unpaired electron. Hence, it will be repelled by the external magnetic field.

Catalytic Properties:

Transition metals and their compounds have catalytic properties.

|

Pt |

Formerly used for SO2 →SO3 in the contact process for making H2SO4. |

|

Pt |

Is increasingly being used in three stage-convertors for cleaning car exhaust fumes. |

|

Pt/Rh |

Formerly used in the Ostwald process for making HNO3 to oxidize NH3 to NO. |

|

Cu |

Is used in the direct process for manufacture of (CH3)2SiCl2 used to make silicones. |

|

Cu/V |

Oxidation of cyclohexanol/cyclohexanone mixtures to adipic acid which is used to make nylon-66. |

|

CuCl2 |

Deacon process of making Cl2 from HCl. |

|

Ni |

Raney nickel, numerous reduction processes (e.g., manufacture of hexamethylenediamine, production of H2 from NH3, reducing anthraquinone to anthraquinol in the production of H2O2) |

|

Ni complexes |

Reppe synthesis (polymerization of alkynes, e.g., to give benzene or cyclooctatetraene. |

|

TiCl3 |

Used as the Ziegler-Natta catalyst in the production of polythene |

|

V2O5 |

Converts SO2 to SO3 in the Contact process for making H2SO4 |

|

MnO2 |

Used as a catalyst to decompose KClO3 to give O2. |

|

Fe |

Promoted iron is used in the Haber—Bosch process for making NH |

|

FeCl3 |

Used in the production of CCl4 from CS2 and Cl2 |

|

FeSO4 & H2O2 |

(Fenton’s reagent) For oxidizing alcohol to aldehyde |

|

PdCl2 |

Wacker process for converting C2H4 + H2O + PdCl2 → CH3CHO + 2HCl + Pd. |

|

Pd |

Used for hydrogenation (e.g. phenol to cylohexanone) |

|

Pt/PtO |

Adams catalyst, used for reductions |

In some cases the transition metals with their variable valency may form unstable intermediate compounds. In other cases the transition metal provides a suitable reaction surface. This is how they behave as catalysts.

Enzymes are catalysts that enhance the rates of specific reactions. They are proteins and are produced by living cells from amino acids. They work under mild conditions and often give 100% yields and may speed a reaction by 106 or 1012 times.

Some enzymes require the presence of metal ions as cofactors. and these are called metalloenzymes. Almost of metalloenzymes contain a transition metal. Some metalloenzymes are listed in following table:

|

Metal |

Enzyme/metalloprotein |

Biological function |

|

Mo |

Xanthine oxidase Nitrate redcatse |

Metabolism of purines Utilization of nitrates |

|

Mn(II) |

Arginase Phosphotransferases |

Urea formation Adding or removing |

|

Fe(II) or (III) |

Aldehyde oxidase Catalase Feroxidase Cytochromes Ferredoxin (Haemoglobin) Succinic dehydrogenase |

Oxidation of aldehydes Decomposes H2O2 Decomposes H2O2 Electron transfer Photosynthesis O2 transport in higher animals Aerobic oxidation of carbohydrates |

|

Fe and Mo |

Nitrogenase |

Fixation of dinitrogen |

|

Co |

Glutamic mutase Ribonucleotide reductase |

Metabolism of amino acids Biosynthesis of DNA |

|

Cu(I) or (II) |

Amine oxidases Ascorbate oxidase Cytochrome oxidase Galactose oxidase Lysine oxidase Dopamine hydroxylase

Tyrosinase Ceruloplasmin (Haemocyani) Plastocyanin |

Oxiation of amines Oxidation of ascorbic acid Principal terminal oxidase Oxidation of galactose Elasticity of aortic walls Producing noradrenaline to generate nerve impulses in the brain Skin pigmentation Utilization of Fe O2 transport in invertebrates Photosyntehsis |

|

Zn(II) |

Alcohol dehydrogenase Alkaline phosphatase Carbonic anhydrase Carboxypeptidase |

Metabolism of alcohol Releasing Regulation of pH and CO2 formation Digestion of proteins |

Nonstoichiometry:

A further feature of the transition elements is that they sometimes form nonstoichiometric compounds. These are compounds of indefinite structure and proportions. For example, iron(II) oxide FeO should be written with a bar over the formula to indicate that the ratio of Fe and O atoms is not exactly 1: 1. Analysis shows that the formula varies between Fe0.94O and Fe0.84O. Vanadium and selenium form a series of compounds ranging from VSe0.98 to VSe2. These have been given the formulae:

Nonstoichiometry is shown among transition metal compounds of the Group 16 elements (O, S, Se, Te). It is mostly due to the variable valency of transition elements. For example copper is precipitated from a solution containing Cu2+ by passing in H2S. The sulphide is completely insoluble, but this is not used as a gravimetric method for analysing for Cu2S because the precipitate is a mixture of CuS and Cu2S. Sometimes nonstoichiometry is caused by defects in the solid structures.

Extraction of iron:

Occurrence: Iron is the fourth most abundant element and the second most abundant metal in nature. It occurs in combined state.

Types of ores:

a. Oxide ores:

(i) Magnetite (Fe3O4) It is usually black in colour. It is richest ore of iron and contains upto 70% of the metal.

(ii) Haematite (Fe2O3) Fe It is usually red in colour.

(iii) Limonite or hydrated ferric oxide (Fe2O3.3H2O) It has yellow, brown or red colour.

b. Carbonate ore:

Siderite or Spathic iron (FeCO3) It is also called clay- iron stone due to the presence of excess of clay in it.

c. Sulphide ores:

(i) Iron pyrites (FeS2) it is mainly used for the manufacture of sulphur dioxide (sulphuric acid). It is not used for extraction of iron.

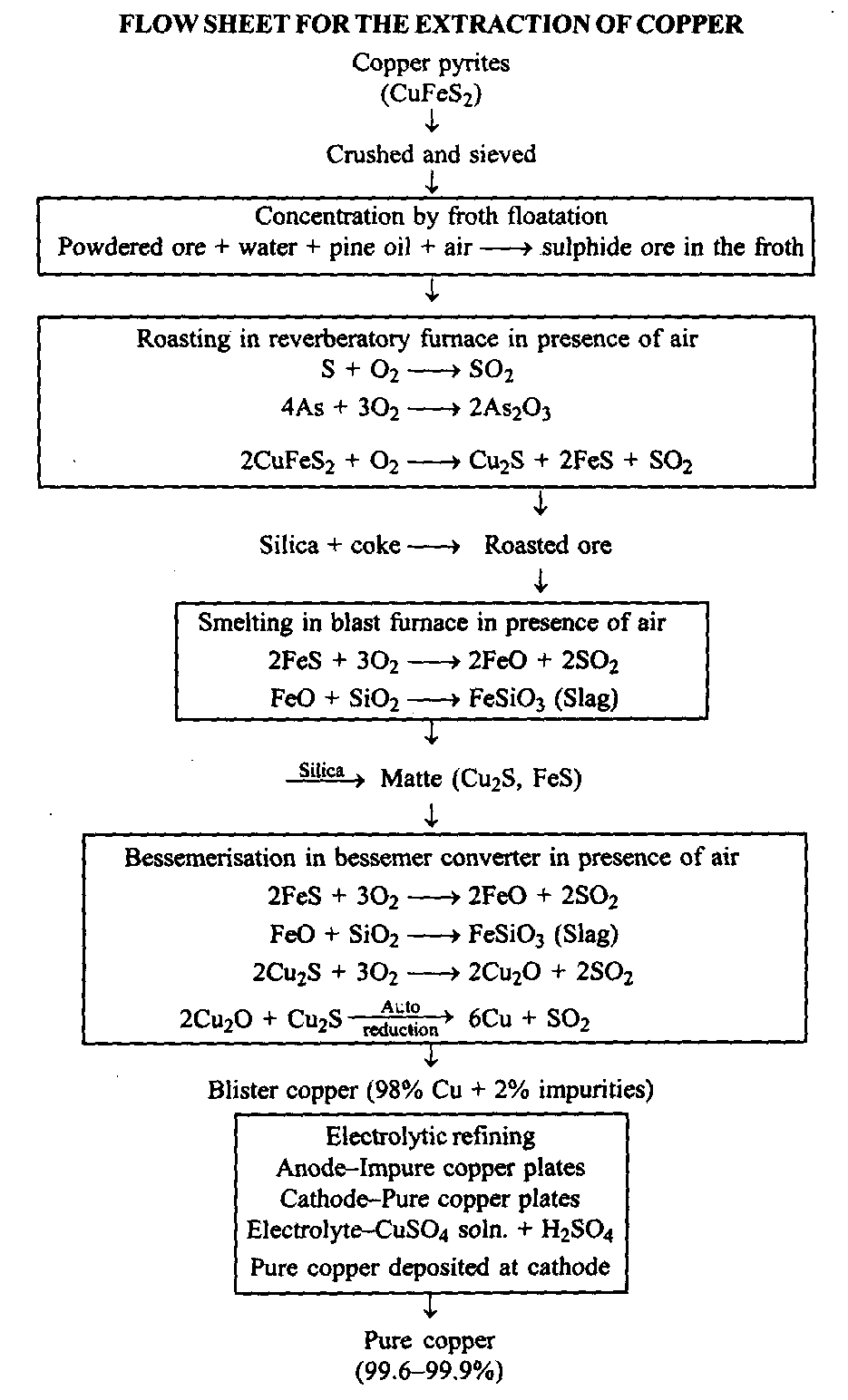

(ii) Chalcopyrites (CuFeS2) It is used for the extraction of copper.

Iron ores have been reported at many places especially in England, Sweden, Germany, U.S.A., Russia, Belgium, France, Canada and India. Huge deposits of red haematite are available in India in Mayurbhanj (Orissa), Singhbhum (Bihar), Madhya Pradesh and Mysore (Karnataka). On the whole, India possesses about one fourth of the total world reserves of iron ore. Iron is extracted from its oxide ores especially from the magnetite, haematite and limonite. The extraction involves the following steps:

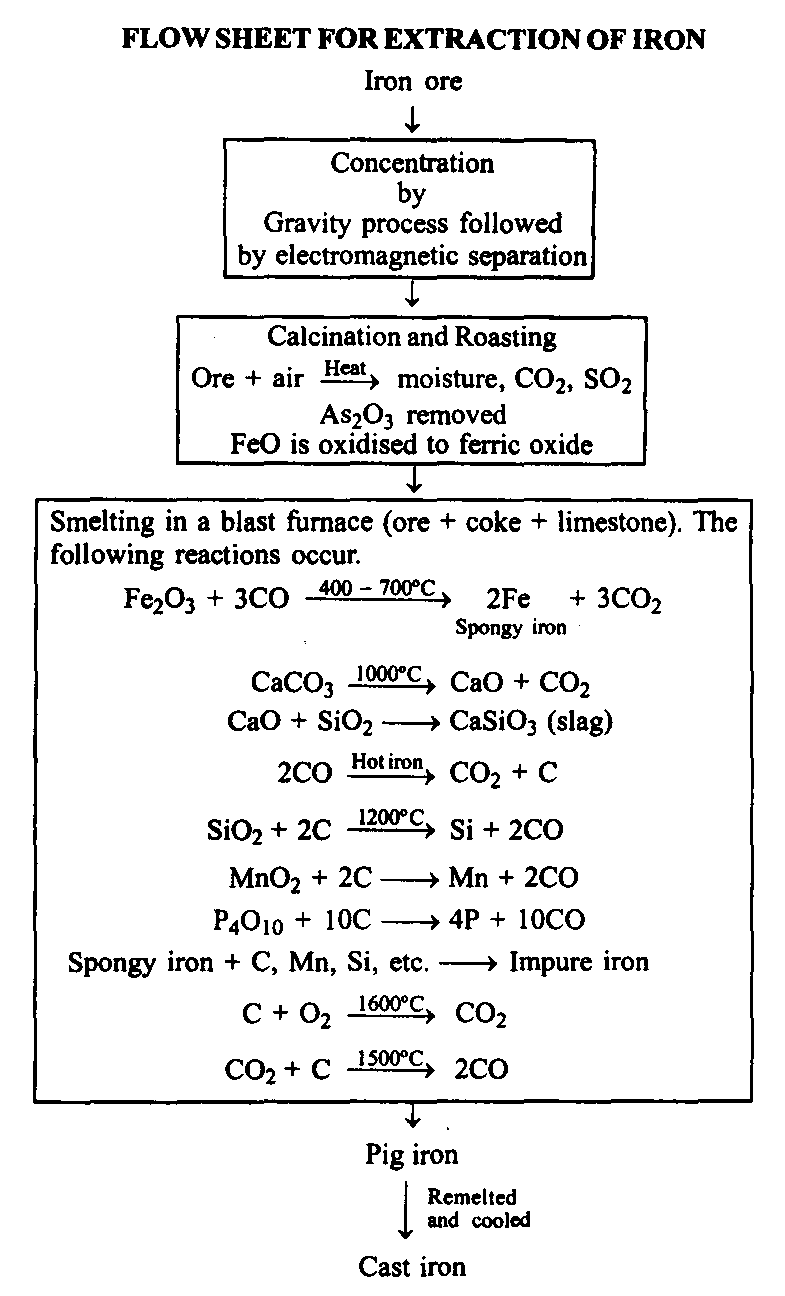

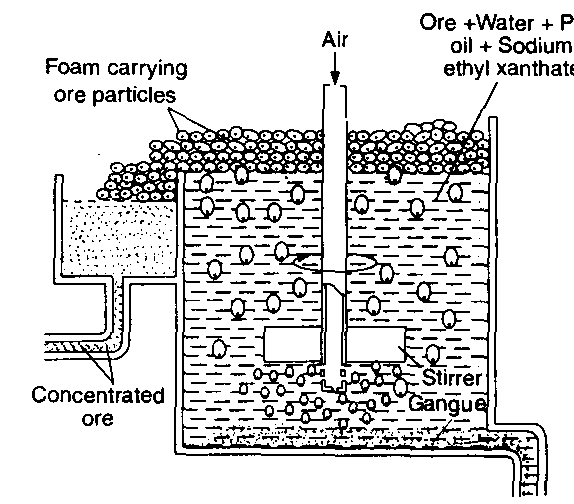

(1) Concentration of ore: The concentration of ore is done by gravity process. The ore is crushed to small pieces and washed with water to remove silicious impurities. The washed ore is then subjected to electromagnetic separation.

(2) Calcination and roasting: The concentrated ore is heated in excess of air. This treatment produces the following results.

(a) Moisture and carbon dioxide are removed.

2Fe2O3.3H2O → 2Fe2O3 + 3H2O

FeCO3 → FeO + CO2

(b) Sulphur, arsenic, etc., are oxidised to their oxides and are, thus, removed as volatile gases.

S + O2 → SO2

4As + 3O2 → 2As2O3

(c) Ferrous oxide is oxidised to ferric oxide.

(d) The entire mass becomes porous.

(Smelting: The calcined ore is mixed with limestone (CaCO and coke in the ratio of S : I : 4 and introduced in a blast furnace for smelting.

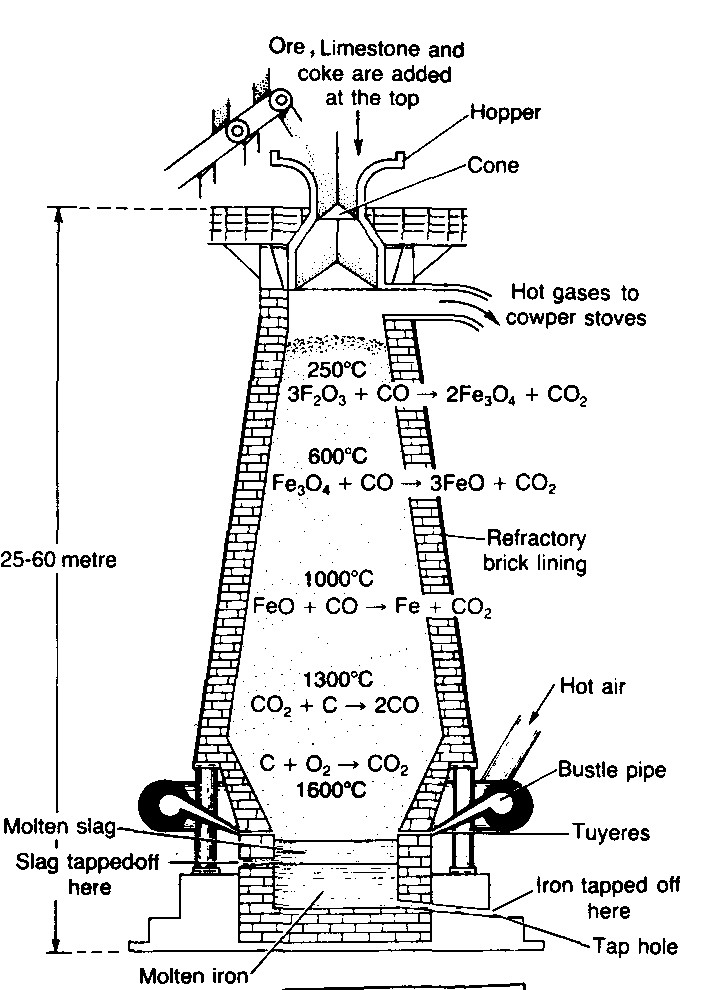

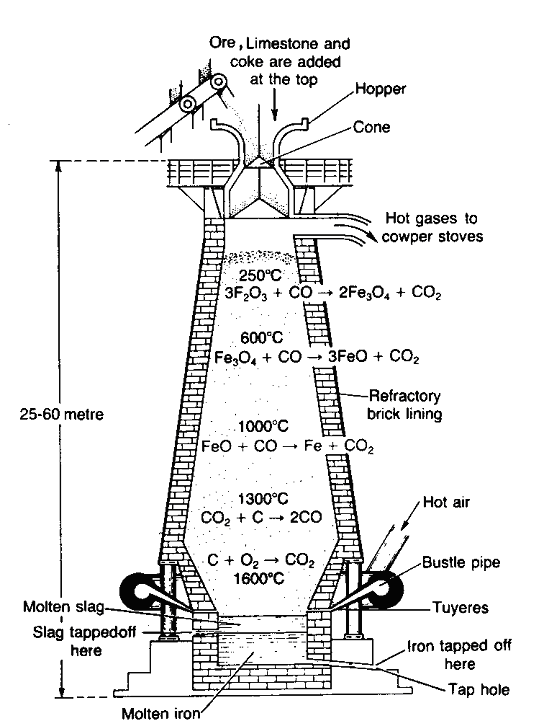

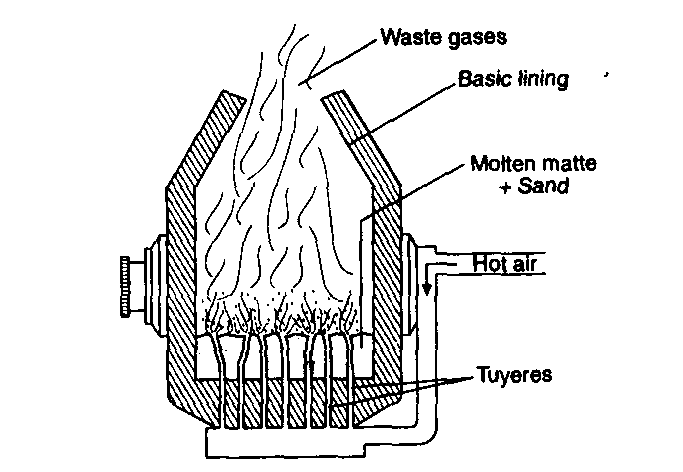

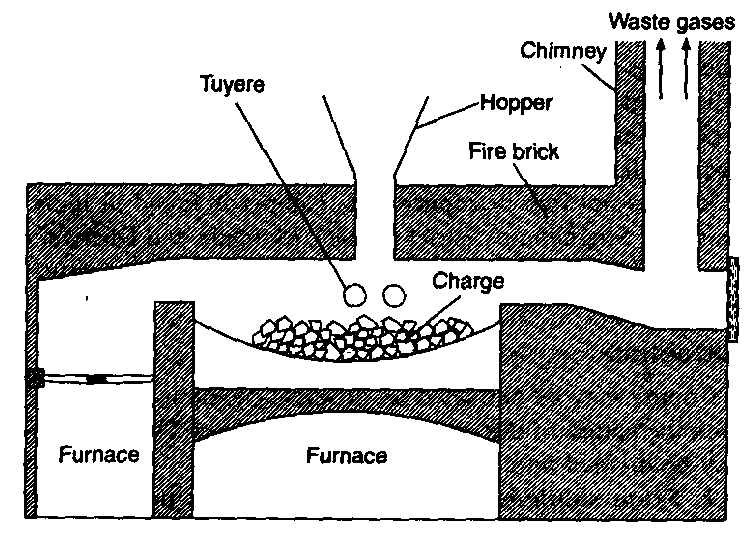

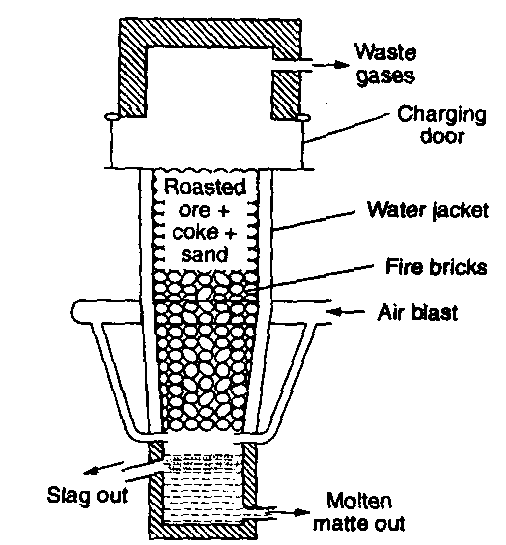

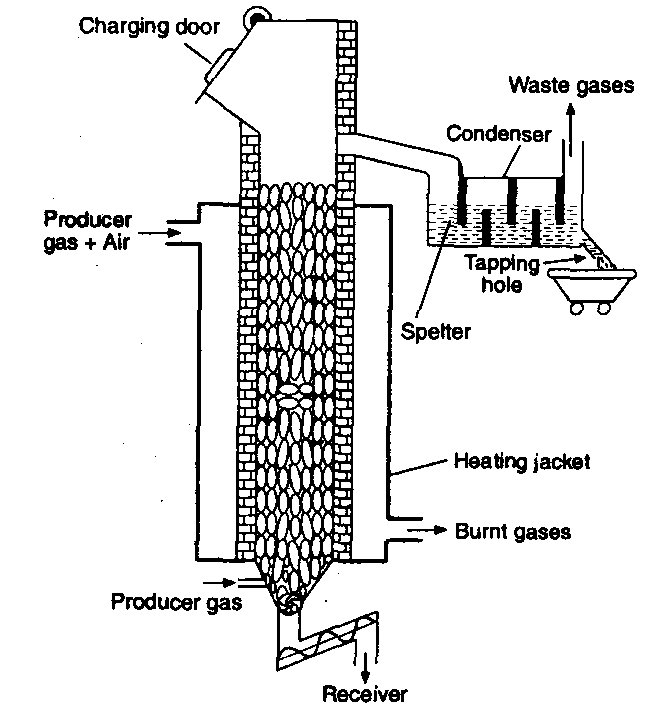

Blast furnace: Blast furnace is a chimney like tall steel structure lined with fire bricks, 25 – 60 metre high and 8-10 metre in diameter at its widest part (see the following figure). The furnace has three main parts:

(i) A double cup and cone arrangement: At the top, the furnace has a hopper which rests over a cup and cone arrangement. By this arrangement charge is introduced into the furnace ant also the arrangement prevents the exit of gases during charging.

(ii) Shaft: It is formed by joining two cones, the upper one is called the body and the lower one is called bosh. At the

upper part, there is a hole, through which the hot burnt mixture of waste gases escape. In the lower part, there are openings for the insertion of water cooled pipes called tuyeres through which a blast of hot air is sent upward in the furnace.

(iii) Hearth: This is the lowest part of the furnace and serves as a large crucible. It is provided with two holes one for the removal of slag and other for molten metal.

The charge is introduced in the furnace by lowering the cup and cone arrangement and at the same time the furnace is lit and a blast of hot air is sent upwards through the tuyeres. The temperature varies from 1600°C to 250°C in the furnace from bottom to top. On the basis of variation in temperature, there are four zones where different chemical changes occur. The four zones are

a. Combustion zone: This is the lowest part of the furnace above hearth where the temperature is about 15000 – 16000 In this zone carbon burns in presence of hot air producing carbon dioxide and a lot of heat.

C + O2 → CO2 + 97.0 k.cals.

Carbon dioxide rises upwards and meets with red hot coke. It is reduced to carbon monoxide.

(iii) Limonite or hydrated ferric oxide, Fe2O3.3H2O. It has yellow, brown or red colour.

b. Carbonate ore: Siderite or Sepathic iron, FeCO3 It is also called clay- iron stone due to the presence of excess of clay in it.

c. Sulphide ores:

(i) Iron pyrites, FeS2 It is mainly used for the manufacture of sulphur dioxide (sulphuric acid). It is not used for extraction of iron.

(ii) Chalcopyrites, CuFeS2 It is used for the extraction of copper.

Iron ores have been reported at many places especially in England, Sweden, Germany, U.S.A.. Russia, Belgium, France, Canada and India. Huge deposits of red haematite are available in India in Mayurbhanj (Orissa), Singhbhum (Bihar), Madhya Pradesh and Mysore (Karnataka). On the whole, India possesses about one fourth of the total world reserves of iron ore.

Iron is extracted from its oxide ores especially from the magnetite, haematite and limonite ores. The extraction involves the following steps.

(I) Concentration of ore: The concentration of ore is done by gravity process. The ore is crushed to small pieces and washed with water to remove silicious impurities. The washed ore is then subjected to electromagnetic separation.

(ii) Calcination and roasting: The concentrated ore is heated in excess of air. This treatment produces the following results.

(a) Moisture and carbon dioxide are removed.

(b) Sulphur, arsenic, etc., are oxidised to their oxides and are, thus, removed as volatile gases.

S + O2 → SO2

4As + 3O2 → 2As2O3

(c) Ferrous oxide is oxidised to ferric oxide.

(d) The entire mass becomes porous.

(3) Smelting: The calcined ore is mixed with limestone (CaCO3) and coke in the ratio of 8 : I : 4 and introduced in a blest furnace for smelting.

Blast furnace: Blast furnace is a chimney like tall steel structure lined with fire bricks, 25-60 metre high and 8-10 metre in diameter at its widest part (Fig. 14.1). The furnace has three main parts:

(1) A double cup. and cone arrangements: At the top, the furnace has a hopper which rests over a cup and cone arrangement. By this arrangement charge is introduced into the furnace an also the arrangement prevents the exit of gases during charging.

(2) Shaft: It is formed by joining two cones, the upper one is called the body and the lower one is called bosh. At the upper part, there is a hole, through which the hot burnt mixture of waste gases escape. In the lower part, there are openings for the insertion of water cooled pipes called tuyeres through which a blast of hot air is sent upward in the furnace.

(3) Hearth : This is the lowest part of the furnace and serves as a large crucible. It is provided with two holes one for the removal of slag and other for molten metal.

The charge is introduced in the furnace by lowering the cup and cone arrangement and at the same time the furnace is lit and a blast of hot air is sent upwards through the tuyeres. The temperature varies from 1600°C to 250°C in the furnace from bottom to top. On the basis of variation in temperature, there are four zones where different chemical changes occur. The four zones are

1. Combustion zone: This is the lowest part of the furnace above hearth where the temperature is about 1500°—I 600°C. In this zone carbon burns in presence of hot air producing carbon dioxide and a lot of heat.

C + O2 → CO2 + 97.0 kcal

Carbon dioxide rises upwards and meets with red hot coke. It is reduced to carbon monoxide.

2. Reduction zone: This is the uppermost part of the furnace. The temperature varies from 250°C to 700°C. The oxide ore is reduced to iron in this zone. The reduction takes place through the following stages:

Iron formed is called spongy iron. In the reduction reactions heat is also evolved which decomposes part of carbon monoxide into carbon.

3. Slag formation zone: This is the central zone where the temperature varies from 800-1000°C. The limestone present in the charge decomposes into calcium oxide and carbon dioxide.

The calcium oxide acts as a flux as it combines with silica present as an impurity (gangue) to form fusible slag of CaSiO3.

CaO + SiO2 → CaSiO3

Silicates, phosphates and manganates present as impurities in ore, are reduced to Si, P and Mn, respectively.

P4O10 + 10C → 4P + 10CO

SiO2 + 2C → Si + 2CO

MnO2 + 2C → Mn + 2CO

These are partly absorbed by iron (spongy) and partly by slag.

2Ca3 (PO3)2 + 3SiO2 + 10C → 3 (2CaO-SiO2) + 4P + 10CO

3Fe + P → Fe3P

4. Zone of fusion: This is a zone just above the zone of combustion. The temperature ranges between 1200—I 500°C. The spongy iron which has absorbed already C, Si, P, Mn, etc., melts at 1300°C and collects at the bottom of the hearth. The slag which being lighter floats over the molten iron and prevents the oxidation of molten metal. The slag and molten metal are removed from their respective holes. The molten metal is run into moulds and is allowed to solidify.

(Fe = 93%; C = 5% and impurities of Mn, 1’, Si, etc. = 2%) Iron obtained from the blast furnace is called pig Iron. It contains 93% iron, 5% carbon and rest silicon, manganese, phosphorus, etc., as impurities. The pig iron is remelted and cast or poured into moulds. This is known as cast iron. Hence, after remelting the pig iron becomes cast iron.

When the molten pig iron is cooled at once, the iron is called white cast Iron, which contains carbon in the form of cementite, Fe and when the molten pig iron is cooled slowly and slowly, the iron is called as grey cast iron, which contains carbon in the form of graphite.

Types of iron:

There are three commercial varieties of iron depending on their carbon content.

( Cast iron: It is the most impure form of iron and contains the highest percentage of carbon from 2.5 to 5 per cent and about 2 per cent of other impurities like Si, P, Mn and S. Cast iron is of two types:

(a) White cast iron: Carbon is present in the form of cementite, Fe

(b) Grey cast iron: Carbon is present in the form of graphite. Cast iron melts at about 1250°C (due to presence of impurities) whereas pure iron melts at 1530°C. The molten cast iron expands on solidification and hence it produces good castings. Various articles such as stoves, pipes, radiators, railway sleepers, gutter pipes, toys, etc., are prepared from cast iron. Cast iron does not rust easily and neither be tempered. Due to high carbon content, it is hard and brittle and cannot be welded. It has very little ductility and thus cast iron is not suitable for forging.

(if) Wrought iron: It is the purest form of iron. It contains the lowest percentage of carbon from 0.1 to 0.25 per cent and 0.3 per cent other impurities. It is manufactured from cast iron by puddling process.

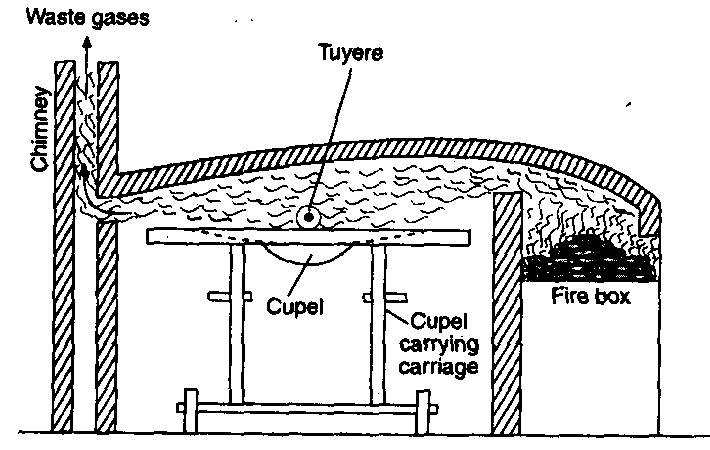

Wrought iron is manufactured in a special type of reverberatory f called puddling furnace, the hearth of which is lined with haematite, Fe The cast iron is melted on the hearth of the furnace by the hot gases and stirred with long iron rods. The impurities of cast iron are rapidly oxidised by oxygen of haematite (lining). Oxides of carbon and sulphur being volatile escape while those of Mn, P and Si form slag.

3C + Fe2O3 → 2Fe + 3CO

3Si + 2Fe2O3 → 3SiO2 + 4Fe

3Mn + fE2O3 → 3MnO + 2Fe

MnO + SiO2 → MnSiO3 (slag)

6P + 5Fe2O3 → 3P2O5 + 10Fe

P2O3 + Fe2O3 → 2FePO4 (slag)

With the removal of impurities, the melting point of the metal rises and it becomes a semi-solid mass. The semi-solid mass is taken out in the form of balls and is beaten under steam hammers to squeeze out as much of slag as possible. This produces almost pure iron known as wrought iron.

Properties: (i) Wrought iron is extremely tough, highly malleable and ductile. (ii) It softens at about 1000°C and then it can be forged and welded. (iii) On account of the presence of very small percentage of slag, it has fibrous structure and thus, can withstand high stresses. (iv) Wrought iron is resistant towards rusting and corrosion.

Uses: It is used to make chains, nails, hooks, bolts, agricultural implements, electromagnets, bars, wires, etc.

(iii) Steel: This is the most important commercial variety of iron. The percentage of carbon in this form of iron is midway between that of cast iron and wrought iron, i.e., 0.25 to 2 per cent. There are many varieties of steel depending on the amount of carbon present in it.

(a) Mild steels: These contain low percentage of carbon. Such steels show the properties of wrought iron along with elasticity and hardness.

(b) Hard steels: These contain high percentage of carbon. They are hard and brittle.

(c) Special steels or alloy steels: Steel mixed with small amount of nickel, cobalt, chromium, tungsten, molybdenum. manganese, etc., acquires special properties. Such products are called special steels or alloy steels. Some important alloy steels are listed below:

|

Name of the alloy steel |

Metal added |

Properties |

Uses |

|

1. Invar |

36% Ni |

Coefficient of expansion is very small |

Measuring tapes pendulums |

|

2. Chromevandium steel |

1% Cr; 0.15%V |

High tensile strength |

Springs, shafts, axles |

|

3. Manganese steel |

12-15% Mn |

Hard and tough |

Rock crushing machinery, almirah, helmets |

|

4. Stainless steel |

11.5% Cr; 2% Ni |

Resists corrosion |

Common articles |

|

5. Tungsten steel |

14-20% W; 3-8 Cr |

Very hard |

High speed tools |

Manufacture of steel: Many methods are used for the manufacture of steel. Some are described below:

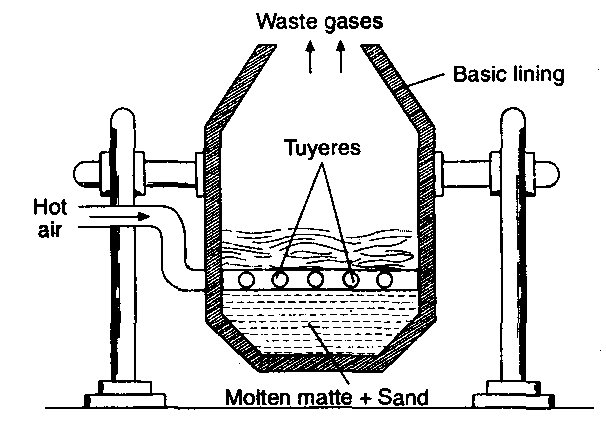

The Bessemer’s process: The process is based on the fact that impurities of pig iron are completely oxidised in

presence of hot air blast, i.e., virtually wrought iron is obtained. This is then mixed with a known amount of spiegeleisen, an alloy of iron, manganese and carbon to obtain steel.

The process is carried out in Bessemer converter lined with silica bricks. The molten pig iron is introduced in the converter and a blast of hot air is blown through it from the bottom and keeping the mouth of the converter vertically upwards. Silica and manganese present in pig iron are first oxidised and then combine to form slag.

Si + O2 → SiO2

2Mn + O2 → 2MnO

MnO + SiO2 → MnSiO3

In the end, carbon is oxidised to carbon monoxide which bums with blue flame at the mouth of the converter. Some iron is also oxidised which converts the carbon into carbon monoxide.

4Fe + 3O2 → 2Fe2O3

Fe2O3 + 3C → 2Fe + 3CO

When whole of the carbon is oxidised, the blue flame suddenly dies out. The air supply is stopped for a while and the requisite amount of spiegeleisen is added. The blast is continued just for a moment to ensure complete mixing. The resulting product is the manganese steel.

When cast iron or pig iron contains phosphorus as an impurity, a basic lining of CaO or MgO is used in the Bessemer converter. Phosphorus is oxidised to P4O10 which combines with CaO to form calcium phosphate as slag.

4P + 5O2 → P4O10

6CaO + P4O10 → 2Ca3(PO4)2

This slag is used as a fertilizer and known as Thomas slag.

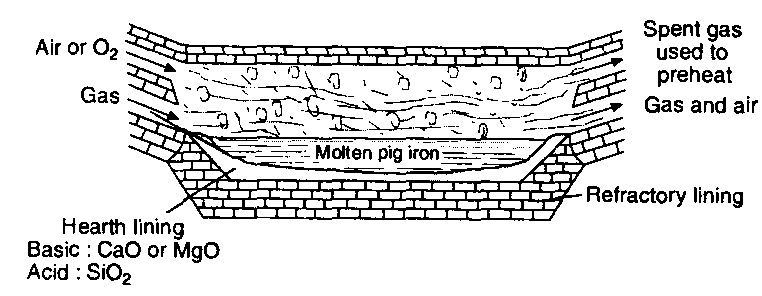

(ii) Open hearth process or Siemens-Martin process:

This is the modern process and the furnace used consists of an open hearth. The hearth is lined with silica or calcined dolomite (CaOMgO) depending upon the nature of impurities present in pig or cast iron. Silica lining is used if the impurities are manganese, silicon, etc., and calcined dolomite lining is used if much of phosphorus is present. A high temperature of about 1500°C is generated by burning producer gas which works on regenerative system of heat economy (Fig).

The charge consists of pig or cast iron, iron scrap, iron ore (haematite) and lime. The charge is heated on the hearth of the furnace. The impurities are oxidised by iron ore.

3Si + 2Fe2O3 → 4Fe + 3SiO2

3Mn + Fe2O3 → 2Fe + 3MnO

MnO + SiO2 → MnSiO3 (slag)

3C + Fe2O3 → 2Fe + 3CO

12P + 10Fe2O3 → 3P4O10 + 20Fe

Samples of steel are drawn from time to time and tested for carbon content. Finally spiegeleisen (an alloy of iron, manganese and carbon) is added to the molten mass to obtain desired steel. The process takes about 8 to 10 hours for completion. The process takes longer time than Bessemer’s process but it has following advantage over the Bessemer’s process.

(a) The temperature can be controlled as the heating is done externally.

(b) As it is a slower process, it can be controlled in better way. The composition and quality can be well controlled.

(c) The loss of iron in this process is only 4% while the loss is about 15% in Bessemer’s process.

(d) In this process scrap iron is re-used.

(e) This yields better quality of steel.

(f) A considerable economy of the fuel is achieved by using the regenerative system.

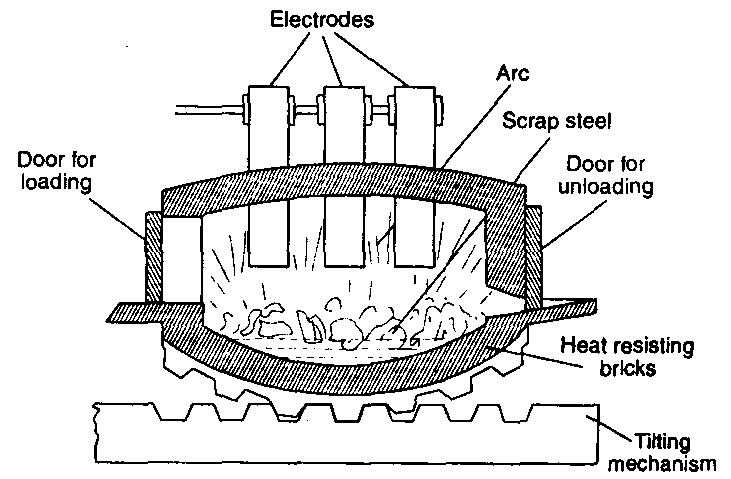

(ill) The electric process : This process is similar to open hearth process with a difference that heating is done electrically. The steel of much better quality can be obtained but the process is rather costly.

The process consists in heating of the charge having pig or cast iron, scrap iron, iron ore (haematite) and lime in an electric furnace using vertical carbon electrodes. When the arc is struck between the electrodes, the high temperature of about 2000°C generated, melts the charge and chemical reactions start instantaneously. The impurities are oxidised by iron ore in the same fashion as in the open hearth process.

This method is especially useful for the production of the alloy steels.

Heat treatment of steels: The properties of steel depend on three factors

(i) Carbon content: With the increase of carbon content the hardness and tensile strength of the steel increases while ductility decreases.

Comparison of Cast Iron, Wrought Iron and Steel:

|

Property |

Cast iron |

Wrought iron |

Steel |

|

1. Chemical composition |

Iron 93 – 95% |

Iron 99.5 – 99.8% |

Iron 99.5-98% |

|

2. Melting point |

Lowest about 12000C |

Highest about 15000C |

Between 1300-14000C |

|

3. Hardness |

Very hard |

Soft |

Medium hardness |

|

4. Malleability |

Brittle |

Malleable |

Malleable and brittle |

|

5. Welding |

Brittle |

Malleable |

Malleable and brittle |

|

6. Tempering |

Cannot be tempered |

Cannot be tempered |

Can be tempered |

|

7. Magnetisation |

Cannot be permanently magnetized |

Magnetisation is not permanent but easy |

Can be permanently magnetized |

|

8. Structure |

Crystalline |

Fibrous |

Granular |

(ii) Presence of other metals: The presence of Si gives steel a fibrous structure. Presence of Mn produces elasticity and increases tensile strength. Cr imparts resistance to chemical action.

(iii) Heat treatment: The hardness and elasticity of the steel can be changed by heating the steel at different temperatures and then allowing to cool it in different ways. The following heat treatments are given to steel

(a) Annealing: It is a process of heating steel to bright redness and then cooling it very slowly. This treatment makes the steel soft and ductile. This type of steel is used in fabrication process.

(b) Quenching: it is a process of heating steel to bright redness and then cooling it suddenly by plunging it in water or oil. Such a steel is extremely hard and brittle. It has very low elasticity.

(c) Tempering: It is a process of heating the quenched steel to a temperature much below redness and then cooling it slowly. Such steel is neither so hard nor so brittle. In the process of tempering, a thin film of the oxide is formed on the surface of steel. The colour of the oxide film depends on the temperature at which the quenched steel is heated.

Temperature range Colour of the oxide film

200 Yellow

225-270°C Brown

300°C Blue

The surface treatment of the steel is done by the following two processes:

(a) Case hardening: The process of producing a thin coating of hardened steel on the surface of the mild steel is called case hardening. This is done by heating the mild steel with charcoal and then plunging into oil. This produces a thin coating of hardened steel on the surface. Such a steel becomes resistant to wear and tear.

(b) Nitriding: The process of producing a hard coating of iron nitride on the surface of steel is called nitriding. Steel is heated in the atmosphere of dry ammonia at 500—600°C for about 3 to 4 days when a hard coating of iron nitride is produced on the surface.

Passivity of Iron:

The following are the common properties of iron.

(a) It evolves hydrogen gas, when made to react with dilute HCI or dilute H2SO4.

(b) It precipitates silver from silver nitrate solution and copper from copper sulphate solution.

But if a piece of iron is first dipped in concentrated nitric acid for sometime and then made to react with the above reagents, neither hydrogen is evolved nor silver or copper are precipitated. Thus, iron by treatment with concentrated nitric acid has lost its usual properties or it has been rendered inert or passive. Such behaviour is not only shown by iron but also by many other metals like Cr, Co, Ni, Al, etc. This phenomenon is known as passivity and the chemical substances which bring passivity are called passivators.

“The inertness exhibited by metals under conditions when chemical activity is to be expected is called chemical passivity.” Iron can be rendered passive by other oxidising agents like chromic acid, KMnO4 conc. H etc. The passivity of the iron is believed to be due to formation of an extremely thin film (invisible) of oxide on the surface of iron. Passive iron can be made active by scratching or heating in a reducing atmosphere of H2 or CO2 or heating in HNO3 upto 75°C.

Compounds of Iron:

Ferrous sulphate (Green vitriol), FeSO4)

This is the best known ferrous salt. It occurs in nature as copperas and is formed by the oxidation of pyrites under the action of water and atmospheric air.

2FeS2 + 7O2 + 2H2O → 2FeSO4 + 2H2SO4

It is commonly known as harakasis.

Preparation: (i) it is obtained by dissolving scrap iron in dilute sulphuric acid.

Fe + H2SO4 → FeSO4 + H2

The solution is crystallised by the addition of alcohol as ferrous sulphate is sparingly soluble in it.

(ii) It can also be prepared in the laboratory from the Kipp’s waste. The excess of sulphuric acid is neutralised by heating with a small quantity of iron fillings. The solution is then crystallised.

Manufacture: Commercially, ferrous sulphate is obtained by the slow oxidation of iron pyrites in the presence of air and moisture. The pyrites are exposed to air in big heaps.

2FeS2 + 2H2O + 7O2 → 2FeSO4 + 2H2SO4

The free sulphuric acid is removed by the addition of scrap iron. On crystallisation green crystals are obtained.

Properties: (i) Hydrated ferrous sulphate (FeSO27H2O) is a green crystalline compound. Due to atmospheric oxidation, the crystals acquire brownish-yellow colour due to formation of basic ferric sulphate.

(ii) Action of heat: At 300°C, it becomes anhydrous.

The anhydrous ferrous sulphate is colourless. The anhydrous salt when strongly heated, breaks up to form ferric oxide with the evolution of SO2 and SO3.

(ii) Action of heat: At 300°C, it becomes anhydrous.

The anhydrous ferrous sulphate is colourless. The anhydrous salt when strongly heated, breaks up to form ferric oxide with the evolution of SO2 and SO3.

(iii) The aqueous solution of ferrous sulphate is slightly acidic due to its hydrolysis.

(iv) Ferrous sulphate is a strong reducing agent.

(a) It decolourises acidified potassium permanganate.

(b) It turns potassium dichromate (acidi&d) green as dichrom is reduced to chroinic salt (green).

(c) it reduces gold chloride to gold.

AuCl3 + 3FeSO4 → Au + Fe2(SO4)3 + FeCl3

(d) it reduces mercuric chloride to mercurous chloride.

(v) A cold solution of ferrous sulphate absorbs nitric oxide forming dark brown addition compound, nitroso ferrous sulphate.

The NO gas is evolved when the solution is heated.

(vi) It forms double sulphate of the composition R2SO4.FeSO4.6H2O where R = an alkali metal or radical.

(NH4)2SO4.FeSO4.6H2O (ferrous ammonium sulphate) is known as Mohr’s salt.

(vii) It combines with potassium cyanide (excess) forming potassium ferrocyanide, K4Fe(CN)6.

Uses : (i) Ferrous sulphate is used for making blue black ink. The ink is prepared by mixing a solution of tannin and ferrous sulphate. A colourless iron salt of tannic acid is formed. A blue dye (usually indigo) is added. The writing with this ink is blue but soon on exposure to air, it becomes black on account of oxidation of colourless ferrous salt into black ferric salt.

(ii) It is used as a mordant in dyeing.

(iii) It is also used as an insecticide in agriculture.

(iv) It is employed as a laboratory reagent and in the preparation of Mohr’s salt.

Ferrous ammonium sulphate (Mohr’s salt)

(NH4)2 SO4. FeSO4. 6H2O:

Preparation: The double salt is best prepared by making saturated solutions of pure ferrous sulphate and pure ammonium sulphate in air free distilled water at 40°C. Both the solutions are mixed and allowed to cool. Generally, few drops of sulphuric acid and a little iron wire are added before crystallisation as to prevent oxidation of ferrous sulphate into ferric sulphate. The salt is obtained as pale green crystals.

Properties: It is pale green crystalline compound which does not effloresce like ferrous sulphate. It is less readily oxidised in the solid state. It is, therefore, a better volumetric reagent in preference to ferrous sulphate. Chemically, it is similar to ferrous sulphate. All the chemical reactions observed in the case of ferrous sulphate are given by ferrous ammonium sulphate.

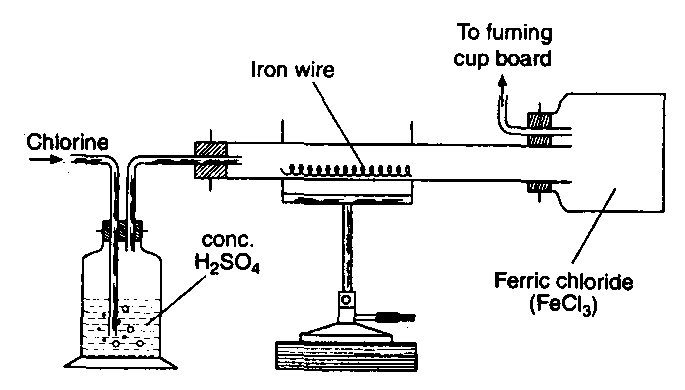

Ferric chloride, FeCI3

This is the most important ferric salt. It is known in anhydrous and hydrated forms. The hydrated form consists of six water molecules, FeCl3CH2O.

Preparation: (i) Anhydrous ferric chloride is obtained by passing dry chlorine gas over heated iron fillings

The vapours are condensed in a bottle attached to the outlet of the tube.

2Fe + 3Cl2 → 2FeCl2

(ii) Hydrated ferric chloride is obtained by the action of hydrochloric acid on ferric carbonate, ferric hydroxide or ferric oxide.

The solution on evaporation and cooling deposits yellow crystals of hydrated ferric chloride, FeCl3

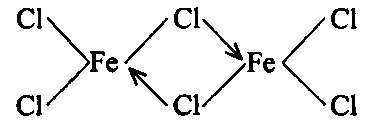

Properties: (i) Anhydrous ferric chloride is a dark red deliquescent solid. It is sublimed at about 300°C and its vapour density corresponds to dimeric formula, Fe The dimer dissociates at high temperatures to FeCl3 The dissociation into Fed is complete at 750°C. Above this temperature it breaks into ferrous chloride and chlorine.

(ii) Anhydrous ferric chloride behaves as a covalent compound as it is soluble in non-polar solvents like ether, alcohol, etc. It is represented by chlorine bridge structure.

(iii) It dissolves in water. The solution is acidic in nature due to its hydrolysis as shown below

The solution is stabilised by the addition of hydrochloric acid to prevent hydrolysis.

(iv) Anhydrous ferric chloride absorbs ammonia.

(v) Ferric chloride acts as an oxidising agent.

(a) It oxidises stannous chloride to stannic chloride.

(b) It oxidises SO2 to H2SO4.

(c) It oxidises H2S to S.

(d) It liberates iodine from KI

(e) Nascent hydrogen reduces FeCl3 into FeCI2.

(vi) When ammonium hydroxide is added to the solution of ferric chloride, a reddish-brown precipitate of ferric hydroxide is formed.

(vii) When a solution of thiocyanate ions is added to ferric chloride solution, a deep red colouration is produced due to formation of a complex salt.

or

(viii) Ferric chloride forms a complex, pussian blue with potassium ferrocyanide.

(ix) On heating hydrated ferric chloride FeCl3.6H2O, anhydrous ferric chloride is not obtained. It is changed to Fe2O3 with evolution of H2O and HCI.

Hydrated ferric chloride may be dehydrated by heating with thionylchloride.

Uses:

(i) The alcoholic solution is used in medicine under the name tincture fern perchloride.

(ii) It is used as a laboratory reagent in the detection of acetates and phenols and also as an oxidising agent.

(iii) It is used for making prussian blue.

Corrosion of iron:

Corrosion Is defined as the gradual transformation of a metal Into its combined state because of the reaction with the environment. Metals are usually extracted from their ores. Nature tries to convert them again into the ore form. The process by which the metals have the tendency to go back to their combined state, is termed corrosion.

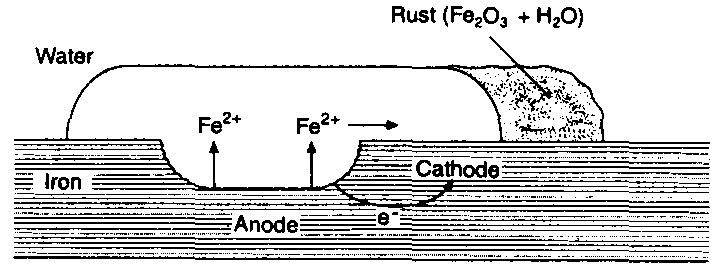

When iron is exposed to moist air, it is found covered with a reddish-brown coating which can easily be detached. The reddish-brown coating is called ‘rust’. Thus, the corrosion of iron or formation of the rust is called rusting. The composition of the rust is not certain but it mainly contains hydrated ferric oxide, 2Fe2O3.3H2O together with a small quantity of ferrous carbonate. The rust is formed by the action of water on iron in presence of dissolved oxygen and carbon dioxide. It has been observed that impure iron is more prone to rusting.

The following are the favourable conditions for the rusting of iron:

(i) Presence of moisture

(ii) Presence of a weakly acidic atmosphere

(iii) Presence of impurity in the iron.

Various theories have been proposed to explain the phenomenon of rusting of iron but the accepted theory is the modern electrochemical theory. When impure iron comes in contact with water containing dissolved carbon dioxide, a voltaic cell is set up. The iron and other impurities act as electrodes while water having dissolved oxygen and carbon dioxide acts as an electrolyte. Iron atoms pass into solution as ferrous ions.

Fe → Fe2+ + 2e

Iron, thus, acts as anode.

The impurities act as cathode. At the cathode, the electrons are used in forming hydroxyl ions.